- Shifting the era of technology-driven Digital Transformation, the business sector aims towards Business Transformation.

- Unveiling the tactics to cultivate a Digital Corporate Culture through People-Process-Technology

Bangkok, 9 January 2024 – “From the confidence in the potential of Thai businesses that can compete globally, leading to True Digital Group’s vision in bring the power of telecommunications infrastructure and digital technology under the strength of True Corporation, a leader in the telecommunication and technology industry to drive business organizations in Thailand across all industries towards sustainable growth through Business Transformation, fostering competitiveness, and elevating agility and capability to tackle with challenges and changes.

“Over the past year after the merger of True and dtac, one of True Corporation’s significant advancements is driving and developing our organization as a Telecom-Tech company that goes beyond being a network provider.” Mr. Ekaraj Panjavinin, Chief Digital Officer of True Corporation Plc. stated under the topic of “Building Corporate Culture for The Future of Digital Manufacturing” at the Automation Summit 2023, the leading knowledge event for industrial sector executives in the digital era. He added that, “True Digital’s mission, underscoring True Corporation’s position as a tech company is ‘Empowering Digital Equity’. We aim to integrate digital services into consumer and business segments to bridge gaps, providing equal access to digital resources, ensuring technology is accessible, affordable, and beneficial. These are not only enrich the digital lifestyle of Thais but also create value for businesses, fostering sustainable growth and contributing to the development of crucial digital infrastructure for the country.”

Entering the decade of Business Transformation, ending of Digital Transformation era

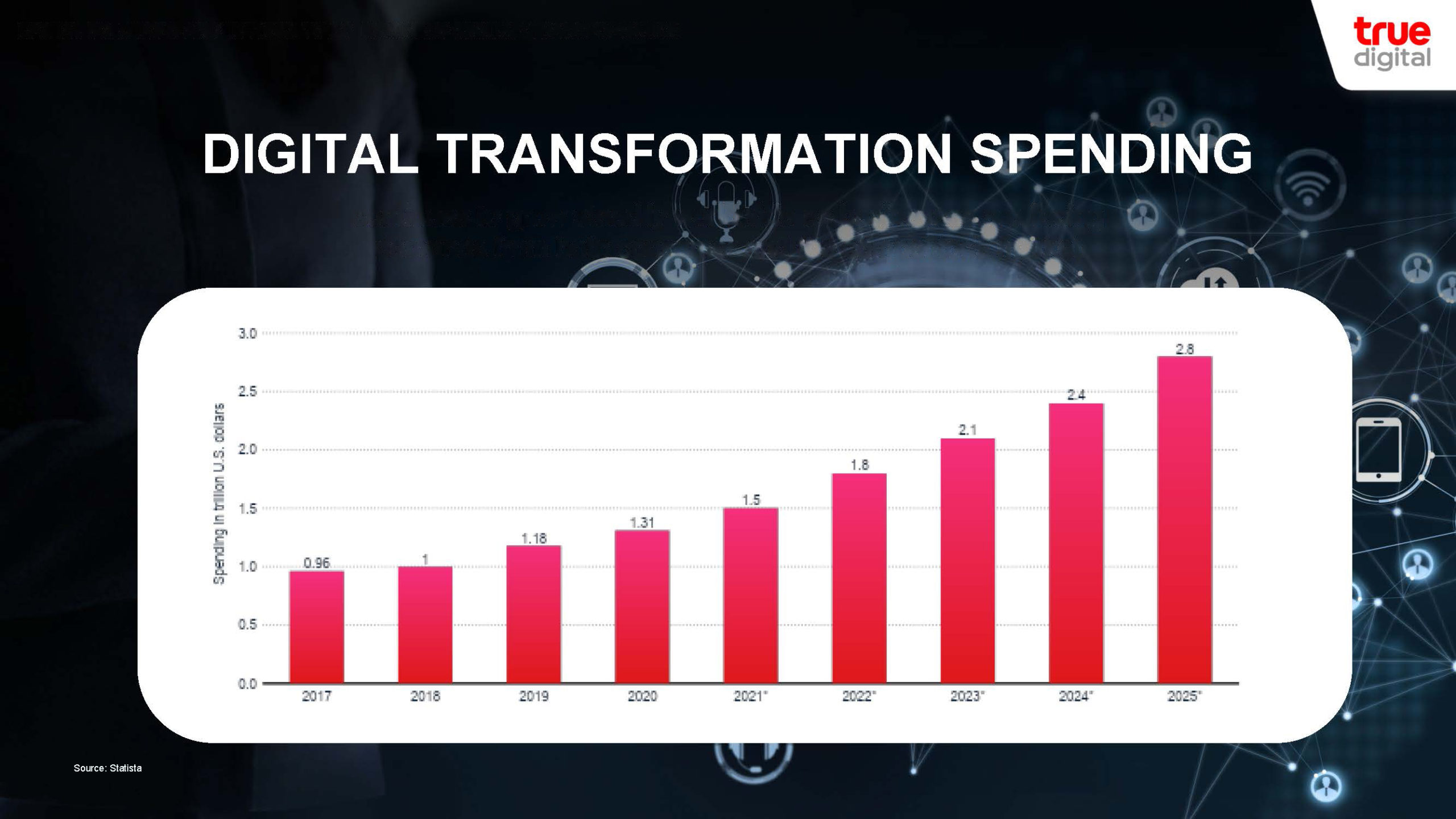

Statista has revealed the global digital transformation spending statistics which have consistently increased every year. The spending reached 2.1 trillion US dollars in 2023, growing more than double when compared to those in last five years. It is anticipated that in the next 1-2 years, spending will surge to almost three trillion US dollars. Mr. Ekaraj pointed out that, “We clearly see that AI technology accelerates the use of digital technology. Businesses are entering an era where the use of digital technology is not just Digital Transformation but shifts to Business Transformation that will create sustainable growth as well as enhance business agility to encounter with the changes, problems, and various challenges. The key to successfully implementing digital technology is to start with the results or ultimate benefits that the organization desires, then choose the technologies that can address and solve the right pain points, and focus on organization’s internal processes integration.

Transformation of traditional producing to Smart Manufacturing

The manufacturing industry faces numerous challenges today, including productivity, quality control, people safety, cost efficiency, opportunities derived from data, and cybersecurity. All these factors drive business owners in the manufacturing industry to adapt and transform businesses to cope with the emerging challenges. Over the past two years, Smart Manufacturing in Thailand has grown significantly. Additionally, the use of IoT technology in Thailand has witnessed the highest growth in Southeast Asia. These statistics clearly reflect the ongoing and rapid trend of transformation in the manufacturing sector. Many factories are transforming from physical to digital, such as implementing digitally based new production lines using simulation or Digital Twins technology. Once the models are complete, they can be immediately deployed in real production lines.

Explore the most popular technology trends driving Smart Manufacturing

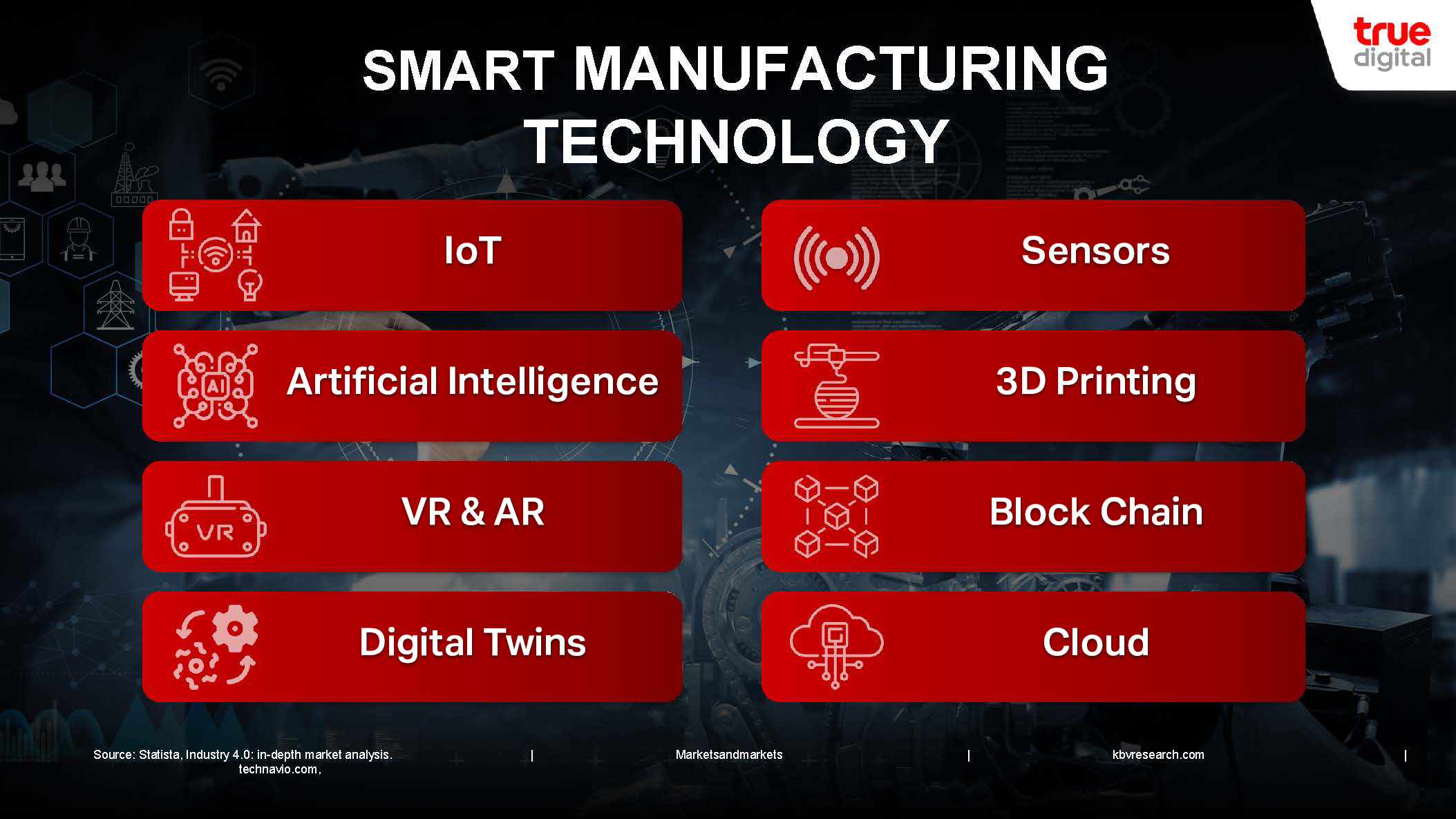

The world’s most popular technologies that creates tremendous business benefits with consistent growth and their usage trend have continuously increased over the next 3 years include:

- Internet of Things (IoT)

- Sensors

- Artificial Intelligence (AI), Machine Learning and Analytics

- VR/AR enhances factory management by utilizing technologies such as troubleshooting machinery through communication with experts via VR/AR glasses.

- Digital Twins are used to create production simulation models.

- Blockchain is utilized to develop innovative Smart Contracts that eliminate intermediaries, providing significant benefits in tracking and tracing of various processes throughout the entire supply chain. Additionally, it can enable governance in factory management by managing critical documents and information. This technology addresses a wide range of needs effectively.

- 3D Printing, creating realistic tangible products in three dimensions, allows for physically touchable and practical implementation.

- Cloud, a versatile data storage space that the cloud service providers can offer various types of services, such as Cloud as a Service

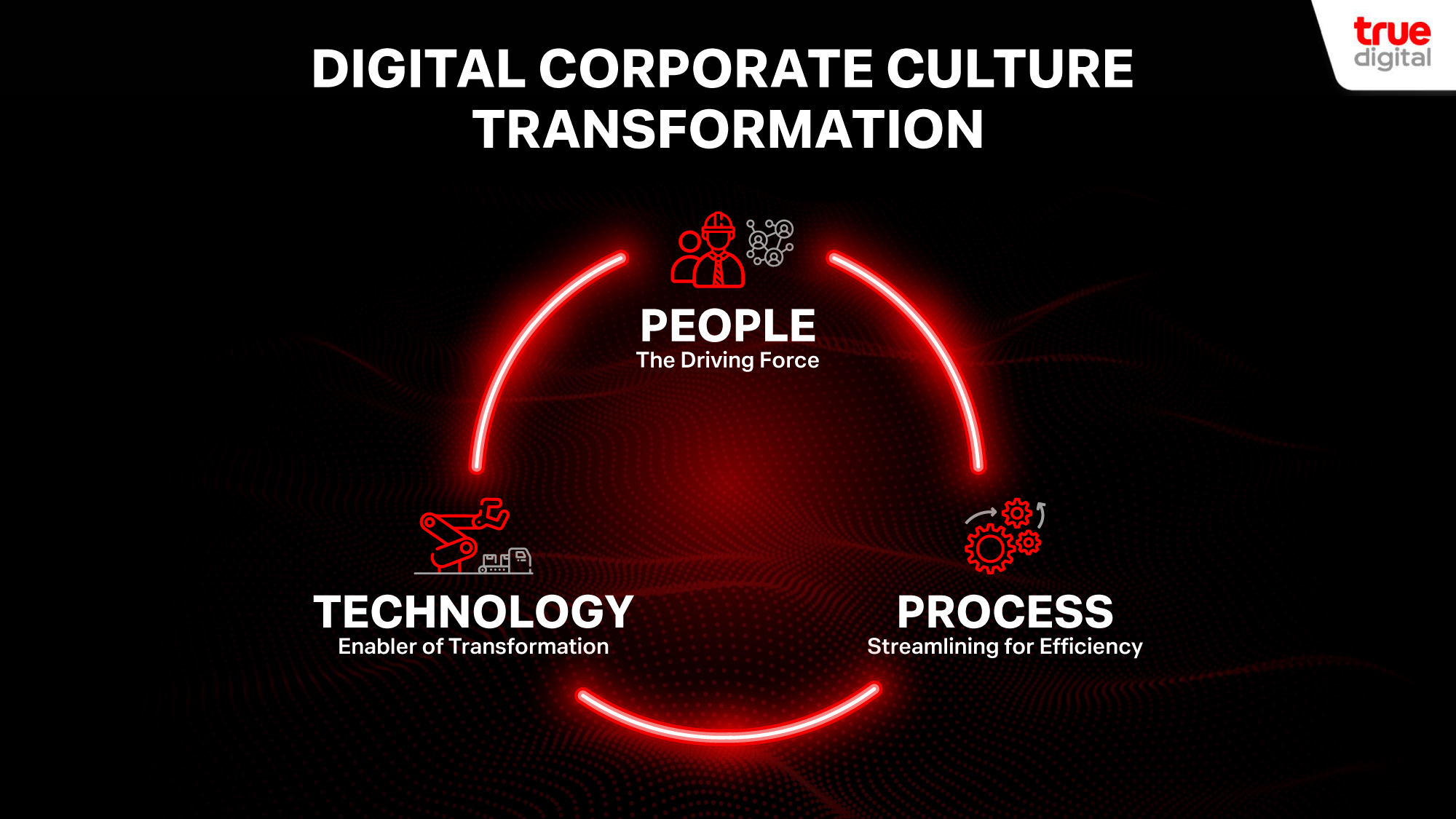

Cultivating a Digital Corporate Culture through People-Process-Technology

When the world’s development moves beyond Digital Transformation, the manufacturing industry needs to cultivate a Digital Corporate Culture, integrating seamlessly with the digital realm. This aims to transform businesses and drive changes that bring maximum benefits to the organization, and can be accomplished with simultaneous development of three key areas: People, Process, and Technology.

People – Employees are valuable resources driving business growth. Organizations should focus on workforce development, starting from assessing the skills and capabilities of their personnel and strategically plan for upskill & reskill. Moreover, management should significantly integrate digital initiatives with the organization’s strategy to drive changes and support employees at all levels in their self-development. This includes fostering collaboration across departments to fully utilize digital systems and empowering employees by allowing them to leverage data, systems, and technologies in line and applying the 3C approach: Connect-Collaborate-Communicate. This approach enhances the potential and elevates the capabilities of employees, fostering positive outcomes for the organization.

Various soft skills required by new era organizations – Amidst the digital transformation, Thailand still faces a shortage of digital talents in various fields such as Data Science, UX/UI, Process Automation, Software Development, and developers. Additionally, a survey of top-level executives in Thailand highlights different soft skills requirement from the last 5 years. The emerging soft skills in demand include Analytical Thinking, Creativity, Adaptability, Leadership, and Native Data Driven skills. The collaborative effort to upskill and reskill employees not only contribute to acquiring the workforce needed for business growth but also elevate the digital capabilities of the Thai workforce.

Process – To achieve work processes transformation, organization need to seamlessly integrate both people and technology. Organizations can start with a simple step – Digitization. This involves selecting certain processes and transforming entirely into digital processes. There’s no need to digitize all process at once. Once gain advantages and impactful results, expansion and further development can be gradually implemented such as Intelligent Process, Automation, Advanced Analytics, Lean Process Design, Business Process Outsourcing, and Robotics. Therefore, simply initiating the digitization of some parts of the factory, whether back-end or front-end, can pave the way for the industrial sector to embark on its digital journey.

Technology – The crucial factor of implementing new technologies is an Open Architecture that allows various systems to connect and extend seamlessly and enables end-to-end solutions by the integration of various technologies. This promotes innovation and efficient utilization of technologies. Additionally, a robust cybersecurity system is essential. There are numerous cutting-edge technologies applicable to the manufacturing industry, moving towards Industry 5.0. These include Human Machine, also known as Humanizing, fostering collaboration between human and technology, more accessible and cost-effective Digital Twins, comprehensive Energy management covering energy usage and Renewable Energy, and seamless Data Transmission & Storage that can be upgraded to Factory Data Lake – a centralized data repository for analysis and processing to derive maximum benefits.

Unlocking Business Transformation

For the organizations aiming to create a Digital Corporate Culture and drive Business Transformation, Mr. Ekaraj recommended an interesting framework for transforming businesses in the digital era by unlocking 1. Vision and Strategy – consistently align digital strategies with business plan 2. Customer Experience and Product – start at the end results, focusing on customer needs or business challenges and utmost organization’s benefits 3. Enabling a data-driven decision-making process 4. Usage of technologies – set KPI to ensure a return on investment in technologies 5. Way of work – foster collaboration and open opportunities for new generations 6. Enabling the right mindset and culture – promote a shared digital mindset and culture among employees 7. Make time for important capability building for self and team and 8. Lead by example, continuous learning and adaptability.

#TrueDigitalGroup